Why Plato Systems?

End-to-End AI Agents for Closed-Loop Operations

End-to-End AI Agents for Closed-Loop Operations

End-to-End AI Agents for Closed-Loop Operations

End-to-End AI Agents for Closed-Loop Operations

Our AI agents pore through your operations data 24/7, identify bottlenecks, pinpoint root causes, and provide real time feedback so that your personnel can continuously drive operational excellence.

Challenges we help with

Process

New tools are needed to drive continuous improvement (Kaizen) and Lean methods in the age of advanced manufacturing and human-machine collaboration.

New tools are needed to drive continuous improvement (Kaizen) and Lean methods in the age of advanced manufacturing and human-machine collaboration.

New tools are needed to drive continuous improvement (Kaizen) and Lean methods in the age of advanced manufacturing and human-machine collaboration.

Workforce

Workforce

Hiring, training, and retaining manufacturing workers is more difficult than ever before. This makes it important to find ways to empower workers to spend their time more effectively by removing repetitive or time-consuming tasks.

Hiring, training, and retaining manufacturing workers is more difficult than ever before. This makes it important to find ways to empower workers to spend their time more effectively by removing repetitive or time-consuming tasks.

Hiring, training, & retaining manufacturing workers is more difficult than ever before. This makes it important to find ways to empower workers to spend their time more effectively by removing repetitive or time-consuming tasks.

Hiring, training, and retaining manufacturing workers is more difficult than ever before. This makes it important to find ways to empower workers to spend their time more effectively by removing repetitive or time-consuming tasks.

Technology

Technology

Existing tools/systems are based on incomplete and/or inaccurate data, operate in open loop with a lot of human intervention, & have yet to show productivity enhancements in many segments.

Existing tools/systems are based on incomplete and/or inaccurate data, operate in open loop with a lot of human intervention, & have yet to show productivity enhancements in many segments.

Existing tools/systems are based on incomplete and/or inaccurate data, operate in open loop with a lot of human intervention, & have yet to show productivity enhancements in many segments.

Plato’s platform streamlines operational excellence

Plato’s platform streamlines operational excellence

Plato’s platform streamlines operational excellence

Plato’s platform streamlines operational excellence

Manufacturing is a complex, dynamic ecosystem where timely detection and root cause analysis of operational issues present significant challenges.

Plato addresses these gaps with a closed-loop operations solution powered by AI agents.

Manufacturing is a complex, dynamic ecosystem where timely detection and root cause analysis of operational issues present significant challenges.

Plato addresses these gaps with a closed-loop operations solution powered by AI agents.

Manufacturing is a complex, dynamic ecosystem where timely detection and root cause analysis of operational issues present significant challenges.

Plato addresses these gaps with a closed-loop operations solution powered by AI agents.

Access to comprehensive data and context provides full context of operations to Plato's AI agents

Access to comprehensive data and context provides full context of operations to Plato's AI agents

Accurate, real-time, and complete factory data that includes the activities of operators (people & AMRs) and interactions with the factory.

Interfaces for integration of data from diverse data streams break data silos by allowing the ingestion of both structured and unstructured data into a unified lakehouse.

Ingested data is standardized into a consistent structure for each domain, ensuring reliability and scalability.

Rapid detection of operational issues and adaptation of models

Rapid detection of operational issues and adaptation of models

Analytic models and AI agents continuously analyze data from all streams across your entire site to provide 24/7 monitoring and observability.

Analytic models and AI agents continuously analyze data from all streams across your entire site to provide 24/7 monitoring and observability.

As more data is observed and models receive feedback over time, they improve and become more powerful.

As more data is observed and models receive feedback over time, they improve and become more powerful.

Real time feedback loops that drive quick corrective actions

Real time feedback loops that drive quick corrective actions

Multiple feedback mechanisms for your personnel and automated systems enable rapid targeted interventions.

Multiple feedback mechanisms for your personnel and automated systems enable rapid targeted interventions.

Feedback loops to humans contain full context of the detected issues so that more time is spent on solving problems than digging through data.

Feedback loops to humans contain full context of the detected issues so that more time is spent on solving problems than digging through data.

Proven results

Increase output by 15% - 30% without additional CapEX

Published case studies with TDK, Skyworks, and Elcon showcasing significant operational improvements and measurable ROI.

Published case studies with TDK, Skyworks, and Elcon showcasing significant operational improvements and measurable ROI.

New tools are needed to drive continuous improvement (Kaizen) and Lean methods in the age of advanced manufacturing and human-machine collaboration.

Deployment in leading companies within the manufacturing industry

Deployment in leading companies within the manufacturing industry

Active deployments in semiconductor fabs, global electronics manufacturing services (EMS) providers, and high-volume, low-mix (HVLM) electronics component manufacturers.

Active deployments in semiconductor fabs, global electronics manufacturing services (EMS) providers, and high-volume, low-mix (HVLM) electronics component manufacturers.

Hiring, training, & retaining manufacturing workers is more difficult than ever before. This makes it important to find ways to empower workers to spend their time more effectively by removing repetitive or time-consuming tasks.

Active deployments in semiconductor fabs, global electronics manufacturing services (EMS) providers, and high-volume, low-mix (HVLM) electronics component manufacturers.

Use cases

Use cases

Use cases

Use cases

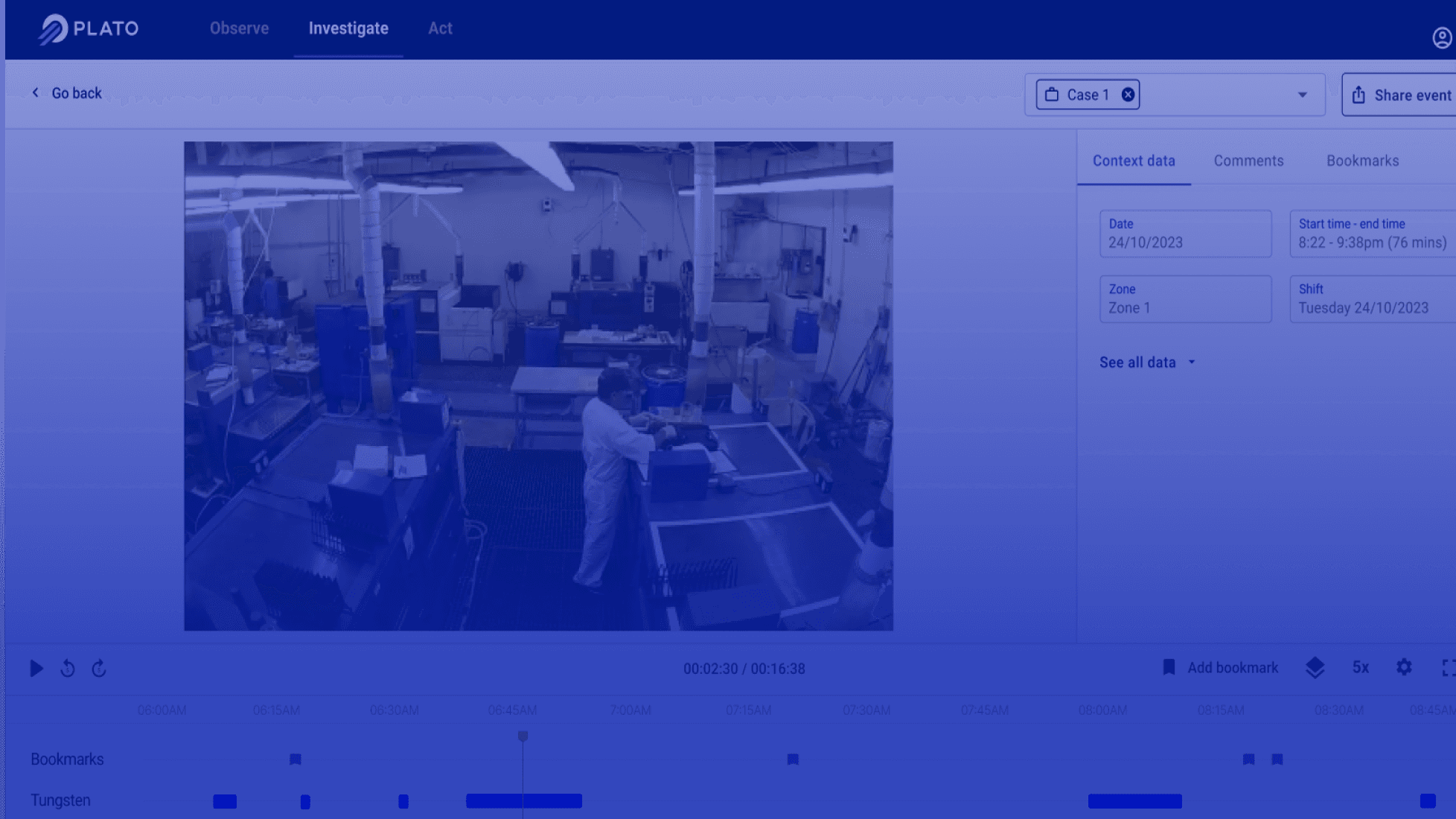

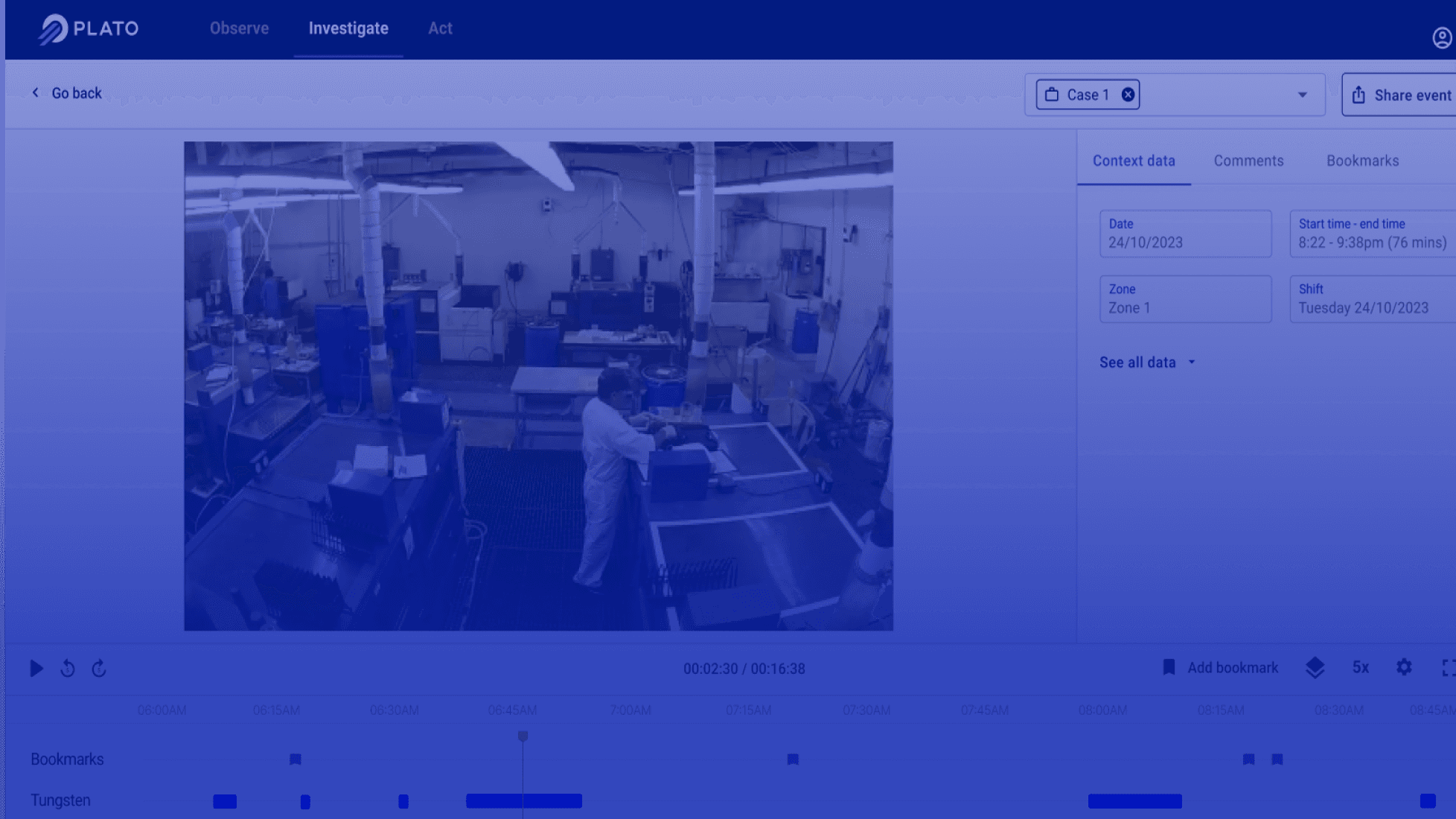

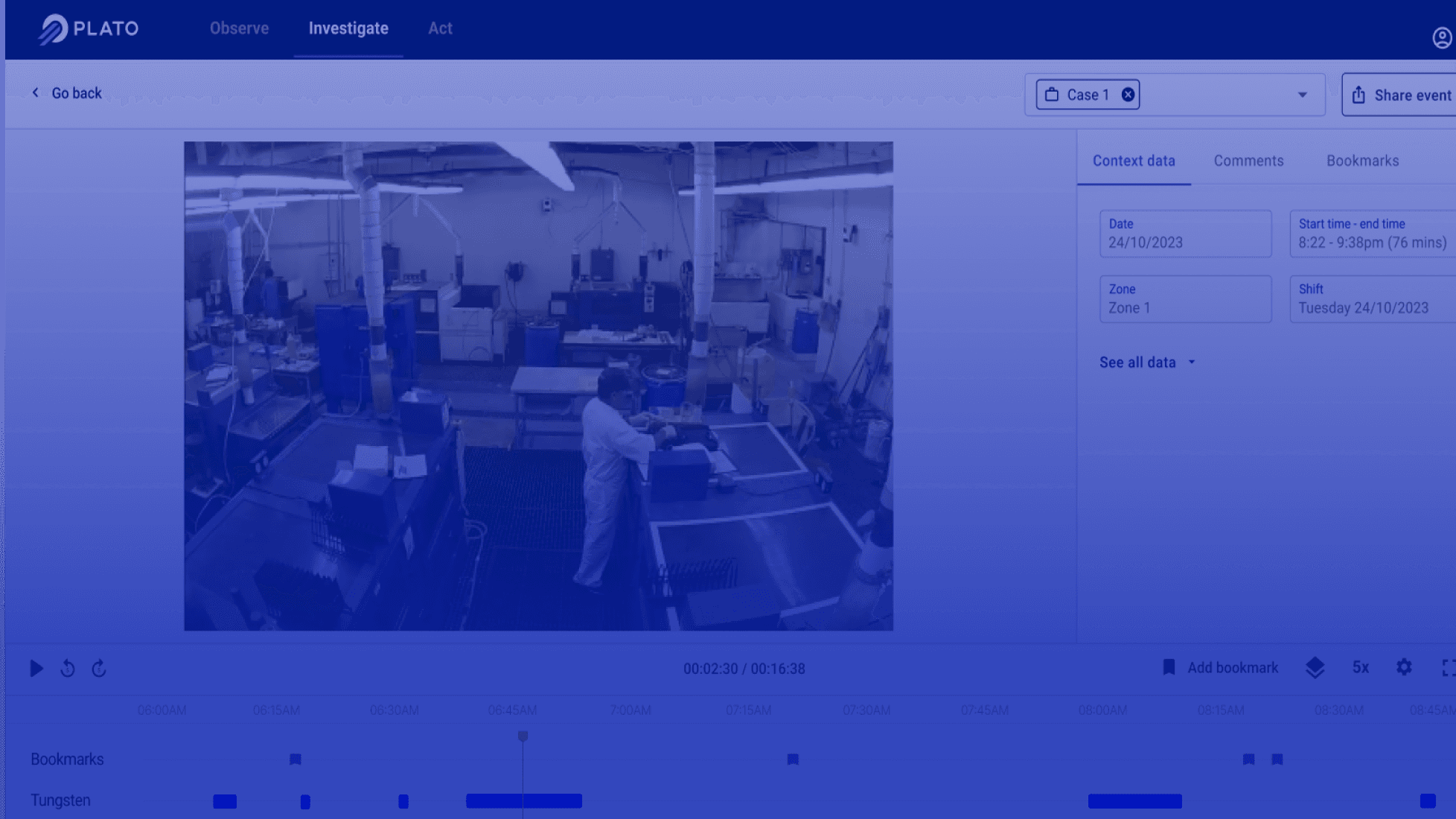

Real-time alerting & guidance about downtime issues

When a machine goes down, our platform instantly detects the issue and notifies the operator responsible for the machine. The operator receives an alert with the machine's location, details of the problem, and step-by-step guidance to resolve it. This ensures rapid response, minimizes downtimes, and keeps production running efficiently.

Real-time alerting & guidance about downtime issues

When a machine goes down, our platform instantly detects the issue and notifies the operator responsible for the machine. The operator receives an alert with the machine's location, details of the problem, and step-by-step guidance to resolve it. This ensures rapid response, minimizes downtimes, and keeps production running efficiently.

Real-time alerting & guidance about downtime issues

When a machine goes down, our platform instantly detects the issue and notifies the operator responsible for the machine. The operator receives an alert with the machine's location, details of the problem, and step-by-step guidance to resolve it. This ensures rapid response, minimizes downtimes, and keeps production running efficiently.

Real-time alerting & guidance about downtime issues

When a machine goes down, our platform instantly detects the issue and notifies the operator responsible for the machine. The operator receives an alert with the machine's location, details of the problem, and step-by-step guidance to resolve it. This ensures rapid response, minimizes downtimes, and keeps production running efficiently.

Spatial Intelligence can be applied across multiple operating environments

Spatial intelligence digitizes operator activity and decision making up and down the electronics supply chain

Spatial Intelligence can be applied across multiple operating environments

Spatial Intelligence can be applied across multiple operating environments

EMS & PCB Assembly

Optimize changeover orchestration

Optimize changeover orchestration

Optimize changeover orchestration

Make material prep more efficient

Make material prep more efficient

Make material prep more efficient

Improve response to line stoppages

Improve response to line stoppages

Improve response to line stoppages

EMS & PCB Assembly

Semiconductor Fabs

Validate operations process models

Validate operations process models

Validate operations process models

Minimize unscheduled idle time

Minimize unscheduled idle time

Minimize unscheduled idle time

Ensure process compliance

Ensure process compliance

Ensure process compliance

Semiconductor Fabs

High-Volume Electronics Component Manufacturing

Maximize OEE by reducing idle times and stoppages

Maximize OEE by reducing idle times and stoppages

Maximize OEE by reducing idle times and stoppages

Optimize changeovers

Optimize changeovers

Optimize changeovers

Increase production capacity

Increase production capacity

Increase production capacity

Semiconductor Fabs

Success stories from our customers

Success stories from our customers

Success stories from our customers

Success stories from our customers

TDK

Learn more about how we helped TDK Components USA root-cause a 20% gap in shift productivity

Learn more

TDK

Learn more about how we helped TDK Components USA root-cause a 20% gap in shift productivity

Learn more

TDK

Learn more about how we helped TDK Components USA root-cause a 20% gap in shift productivity

Learn more

Skyworks

Discover how Skyworks Solutions unleashed operational excellence with AI-enabled Spatial Intelligence

Learn more

Skyworks

Discover how Skyworks Solutions unleashed operational excellence with AI-enabled Spatial Intelligence

Learn more

Skyworks

Discover how Skyworks Solutions unleashed operational excellence with AI-enabled Spatial Intelligence

Learn more

Elcon Precision

Explore how objective observability helped Elcon Precision unlock operational efficiency

Learn more

Elcon Precision

Explore how objective observability helped Elcon Precision unlock operational efficiency

Learn more

Elcon Precision

Explore how objective observability helped Elcon Precision unlock operational efficiency

Learn more

Book a call and get started with Plato Systems

Book a call and get started with Plato Systems

Book a call and get started with Plato Systems

Book a call and get started with Plato Systems

© 2024 Plato Systems Inc. All rights reserved.

© 2024 Plato Systems Inc. All rights reserved.

Contact

Contact

360 Pine St, Floor 6

San Francisco, CA 94104

360 Pine St, Floor 6

San Francisco, CA 94104

360 Pine St, Floor 6

San Francisco, CA 94104