Why Plato?

Plato digitizes operator-machine interactions at scale and uses this information to optimize production, minimize downtimes and variations across lines and shifts, and provide targeted training material to operators. We are taking optimization of operations & processes to the AI era.

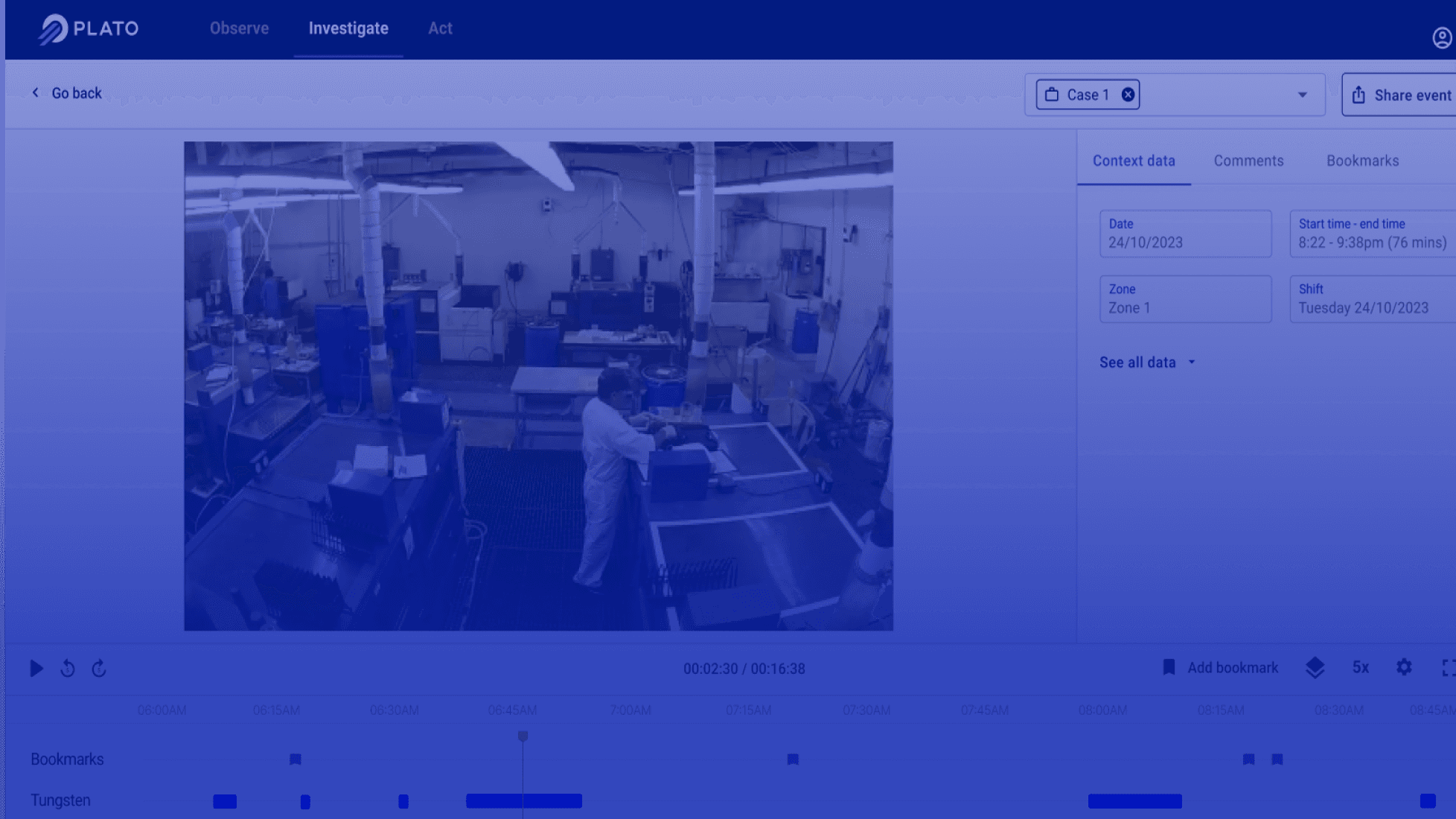

Plato's Spatial Intelligence platform, powered by NVIDIA Metropolis, enhances AI agents' spatial reasoning for various visual tasks. Factories can now drive faster process improvement cycles using self-service AI agents that analyze large volumes of multi-modal data to extract valuable insights and act based on them.

Plato’s Deep Fusion combines computer vision and mmWave radar for Tagless Activity Tracking™

First AI platform to digitize operator-machine interactions and create a full Operations Digital Twin.

Boost production with holistic observability, OEE tools, root-cause analysis, and workforce training—no extra CapEx or labor!

Advanced manufacturing facilities cost from tens of millions to more than $10B for a state-of-the-art semiconductor fab.

Geopolitics are reshaping and localizing supply chains.

Maximizing Overall Equipment Effectiveness (OEE) is crucial in order to achieve higher production rates without additional CapEx.

68% of $1B manufacturers are pursuing digital transformation, up from 43% in 2017.

Only 14% of these manufacturers consider their projects successful.

Labor productivity has dropped by 2% in recent years.

The US faces a 2.1M skilled worker shortage by 2030.

Manufacturing turnover rates are at 40%.

Over 50% of manufacturing workers are 45 or older, and this trend is growing.

Data collection, integration and unification

Learn more

Cloud infrastructure for AI Agents

Learn more

Insights & Actions

Learn more

Mario R.

Sr. Manager of Operations at Leading Semiconductor Manufacturer

James S.

Production Manager at Elcon Precision